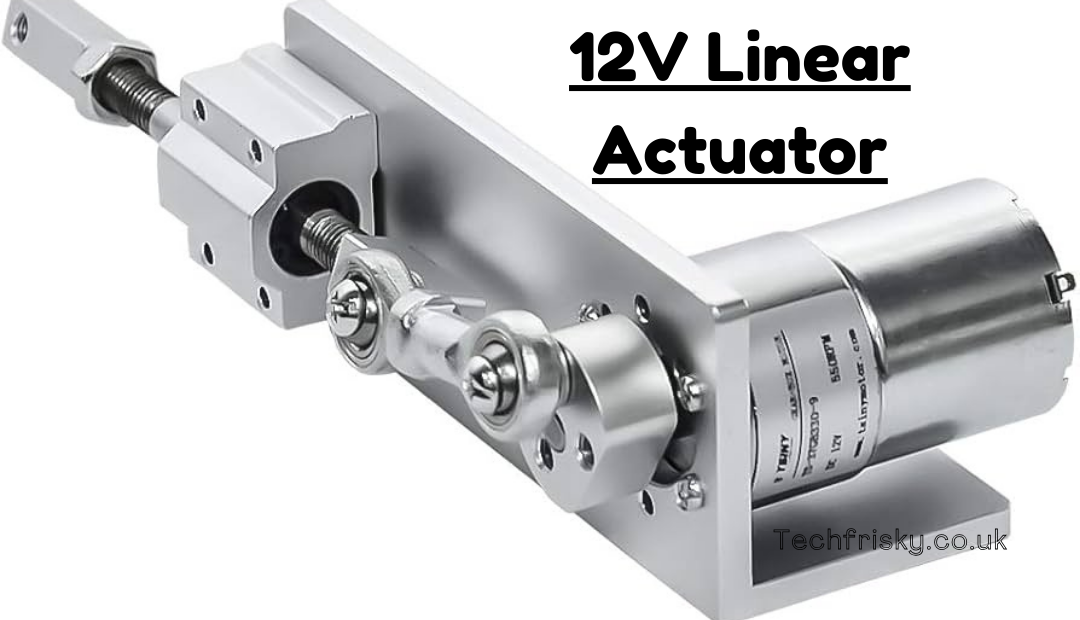

A 12V linear actuator is an electromechanical device designed to create linear motion using a 12-volt power source. It converts electrical energy into mechanical movement, allowing it to push, pull, lift, or adjust objects along a straight path. Due to its compatibility with standard 12V systems, it’s widely used in automotive applications, solar panels, home automation, and more. Its efficient power needs and flexibility make it ideal for various indoor and outdoor applications where controlled, precise movement is essential.

Key Components of a 12V Linear Actuator

The typical 12V linear actuator consists of several essential parts:

- Electric Motor: Converts the electrical energy from the 12V source into rotational movement.

- Gearbox: Adjusts the motor’s speed and torque to meet the actuator’s required output force.

- Lead Screw and Nut: Transforms the rotational motion from the motor into a linear movement.

- Limit Switches: Prevent overextension by cutting off power when the actuator reaches its limit.

Each component has a specific role, working together to provide accurate and controlled linear motion. These features allow the actuator to achieve dependable performance in various applications.

How Does a 12V Linear Actuator Work?

A linear actuator 12v operates by using an electric motor to create rotational motion, which is then converted into linear motion by a lead screw. When power is applied, the motor begins to rotate, causing the lead screw to move the actuator’s shaft in or out. This linear movement allows the actuator to push or pull loads based on the direction of the current. Limit switches ensure the actuator stops at the desired positions, preventing damage from overextension.

The 12V voltage level provides a convenient and safe power option, commonly used in vehicles, off-grid systems, and household applications.

Advantages of Using a 12V Linear Actuator

12V linear actuators offer numerous benefits that make them highly sought after for applications requiring compact, controlled linear motion. Key advantages include:

- Compact and Lightweight: Ideal for applications where space is limited.

- Low Power Consumption: Operates efficiently on a standard 12V battery or power supply.

- Ease of Integration: Easily incorporated into various systems, from home automation to vehicles.

- Precision Control: Provides accurate movement, allowing precise adjustments.

These advantages make linear actuator 12v particularly suitable for applications in automotive and home automation, where reliable, compact solutions are essential.

Common Applications of 12V Linear Actuators

heavy duty linear actuator 12v are versatile and used across various industries:

- Automotive: For power seating adjustments, tailgates, and hatch mechanisms.

- Solar Tracking Systems: Move solar panels to optimize sun exposure.

- Home Automation: In applications like automated windows, sliding doors, and adjustable furniture.

- Agriculture: Used in machinery for planting and harvesting operations.

- Healthcare: Provides smooth, controlled motion in adjustable hospital beds and patient lifts.

The adaptability of linear actuator 12v makes them a popular choice across these industries, as they offer durability, simplicity, and efficiency in diverse settings.

Types of 12V Linear Actuators

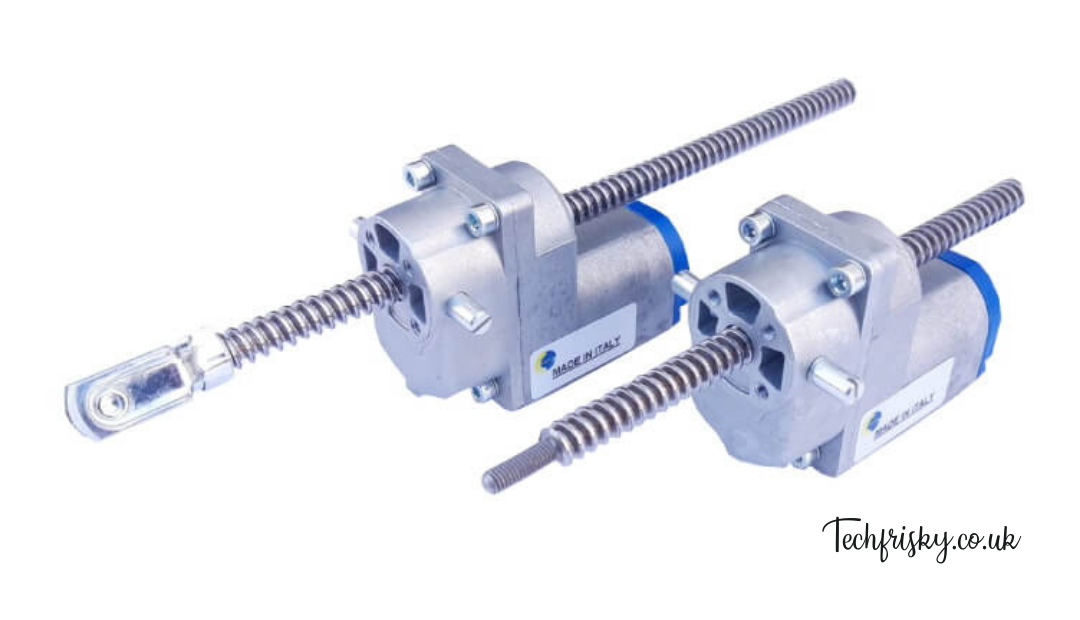

There are several types of 12V linear actuators, each suited for specific applications:

- Standard Linear Actuators: Offer straightforward linear motion, ideal for general-purpose applications.

- Mini Linear Actuators: Compact versions, perfect for applications with limited space.

- Heavy-Duty Linear Actuators: Built for high-force applications, capable of lifting heavier loads.

- High-Speed Actuators: Designed for applications where quick adjustments are necessary.

- Feedback Linear Actuators: Equipped with feedback sensors for precise positioning control.

Selecting the correct type depends on the application requirements, including speed, load capacity, and space constraints.

Installation and Mounting of 12V Linear Actuators

Installing a heavy duty linear actuator 12v typically involves securing it to a mounting surface and ensuring it aligns properly with the load. Basic installation steps include:

- Secure Mounting Brackets: Attach the actuator to the mounting surface using suitable brackets.

- Electrical Connection: Connect the actuator to a 12V power source and control system.

- Limit Switch Setup: Ensure limit switches are set to avoid overextension or retraction.

- Test the Movement: Operate the actuator to confirm smooth movement and positioning.

Correct installation is crucial to prevent wear and maximize the actuator’s lifespan. Using compatible mounting brackets and proper alignment can improve efficiency and prevent operational issues.

Customization Options for 12V Linear Actuators

Many linear actuator 12v offer customization options to fit specific needs:

- Stroke Length: Varies the distance the actuator can extend and retract.

- Force Capacity: Adjustable based on load requirements.

- Speed and Control Options: Available with different speed settings and manual or automated control mechanisms.

These customizable features make 12V actuators adaptable to diverse applications, allowing users to select a model that best meets their performance requirements.

Maintenance and Longevity of 12V Linear Actuators

linear actuators 12v are designed for durability, but regular maintenance can help maximize their lifespan:

- Inspect for Wear: Regularly check for signs of wear in the motor, lead screw, and other moving parts.

- Lubricate Moving Parts: Reduce friction by keeping components properly lubricated.

- Clean the Actuator: Prevent dirt and debris buildup, which can affect operation.

- Check Electrical Connections: Ensure secure and corrosion-free connections.

Routine maintenance ensures smooth operation, reduces the risk of malfunctions, and extends the actuator’s useful life.

Common Issues and Troubleshooting Tips for 12V Linear Actuators

While reliable, linear actuators 12v may occasionally encounter issues, such as:

- Stalling or Slow Movement: Often due to insufficient power supply or mechanical obstructions.

- Overheating: Continuous operation without breaks can cause overheating.

- Inconsistent Motion: Can result from a worn lead screw or incorrect alignment.

To troubleshoot, start by checking the power supply, ensuring the actuator has proper clearance, and inspecting for wear. Regular maintenance can prevent most issues and keep the actuator in peak condition.

Safety Considerations for 12V Linear Actuators

Safety is essential when operating 12V linear actuators, especially in applications involving significant loads. Common safety features include:

- Overload Protection: Prevents the actuator from exceeding its rated load capacity.

- Automatic Shut-Off: Limit switches or sensors stop the actuator at end positions, protecting it from overextension.

- Emergency Manual Control: Allows manual adjustment in case of power failure.

Using actuators with built-in safety features reduces the risk of accidents and enhances operational reliability.

Future Innovations in 12V Linear Actuator Technology

Future advancements in linear actuators 12v technology are set to enhance performance and versatility:

- Smart Actuators: Integration with IoT for remote control and real-time diagnostics.

- Energy Efficiency Improvements: Enhanced motor designs to reduce power consumption.

- Advanced Materials: Lightweight, durable materials that extend lifespan and reduce wear.

- Precision Feedback Mechanisms: Higher accuracy in positioning, ideal for automation applications.

These innovations promise to expand the capabilities of 12V linear actuators, making them more efficient and adaptable to new technological demands.

Choosing the Right 12V Linear Actuator for Your Needs

Selecting the ideal linear actuators 12v involves assessing factors like:

- Load and Force Requirements: Ensure the actuator can handle the intended weight or force.

- Stroke Length: Consider the required range of movement.

- Speed Requirements: Select based on the need for fast or slow motion.

- Environmental Conditions: For outdoor or harsh environments, choose a weather-resistant model.

Choosing the right 12V linear actuator tailored to your specific requirements will enhance performance and ensure efficient operation.

Conclusion: The Value of 12V Linear Actuators in Modern Applications

12V linear actuators are indispensable tools for achieving controlled, linear motion in a wide range of applications. Their versatility, efficiency, and precision make them ideal for sectors as diverse as automotive, home automation, and solar power systems. With continued advancements in technology, linear actuator 12v waterproof are becoming more energy-efficient and customizable, paving the way for even broader usage.

For anyone needing reliable, precise motion control, a linear actuator 12v waterproof represents a compact, durable, and highly efficient solution, capable of adapting to future needs and evolving applications.