Electric actuators play a pivotal role in automation, providing precise motion control by converting electrical energy into mechanical movement. Unlike their hydraulic and pneumatic counterparts, throttle actuator assembly for an electric boatare often preferred due to their energy efficiency, ease of installation, and environmental friendliness. They drive various technologies, from small consumer electronics to large industrial machinery, showcasing their versatility across numerous sectors.

What are Electric Actuators and Why They Matter?

Electric actuators excel in situations demanding high levels of control and accuracy, making them ideal for applications such as robotics, automotive components, and automated manufacturing systems. Their capacity to offer fine-tuned control with minimal energy wastage marks a significant advancement over traditional options.

Understanding Actuators: Types and Their Applications

Actuators transform energy into motion. They can be categorized as:

- Mechanical Actuators: Utilize levers, gears, or cams for mechanical motion.

- Hydraulic Actuators: Depend on pressurized fluid, usually for heavy-duty applications.

- Pneumatic Actuators: Use compressed air for quick, repetitive tasks.

- Electric Actuators: Employ electric power, highly suited for precision and control.

throttle actuator assembly for an electric boat stand out among these due to their versatility, offering quieter operation, increased efficiency, and simplified maintenance.

Why Choose Electric Actuators Over Others?

throttle actuator assembly for an electric boat rv4daysd602a are designed for precision and ease of integration with modern control systems. Their advantages include:

- Energy Efficiency: throttle actuator assembly for an electric boat rv4daysd602a generally consume less power.

- Low Maintenance: Reduced reliance on fluids means fewer leakages and contaminants.

- Environmental Benefits: Without the use of hydraulic fluids, they are more eco-friendly.

- Operational Flexibility: Easily controlled with electronic systems, ideal for automation.

These attributes make throttle actuator assembly for an electric boat a preferred choice in industries prioritizing precision, reliability, and sustainability.

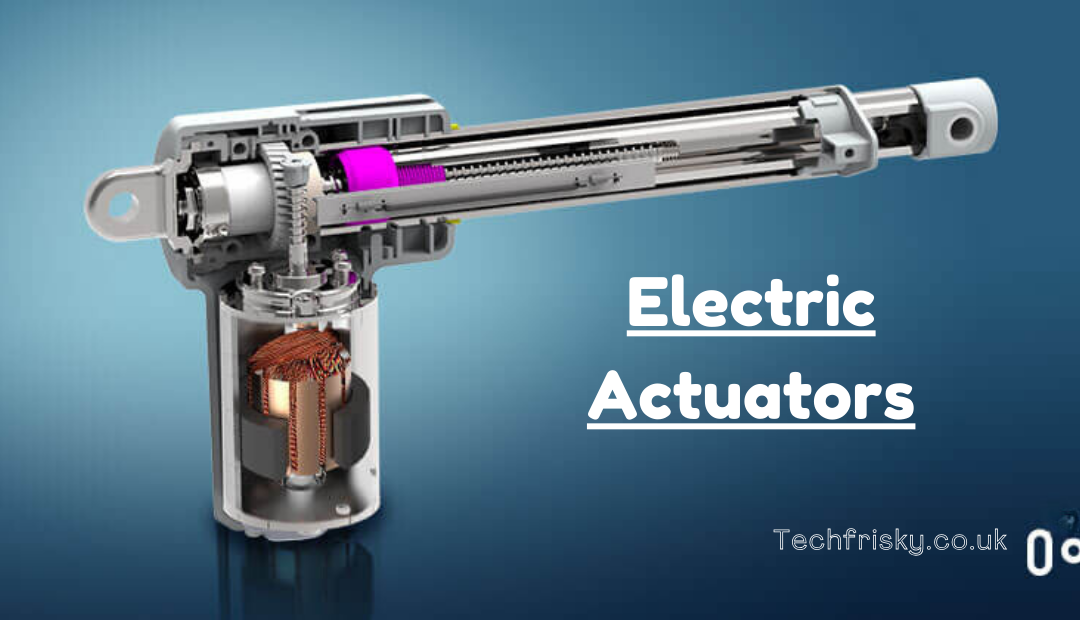

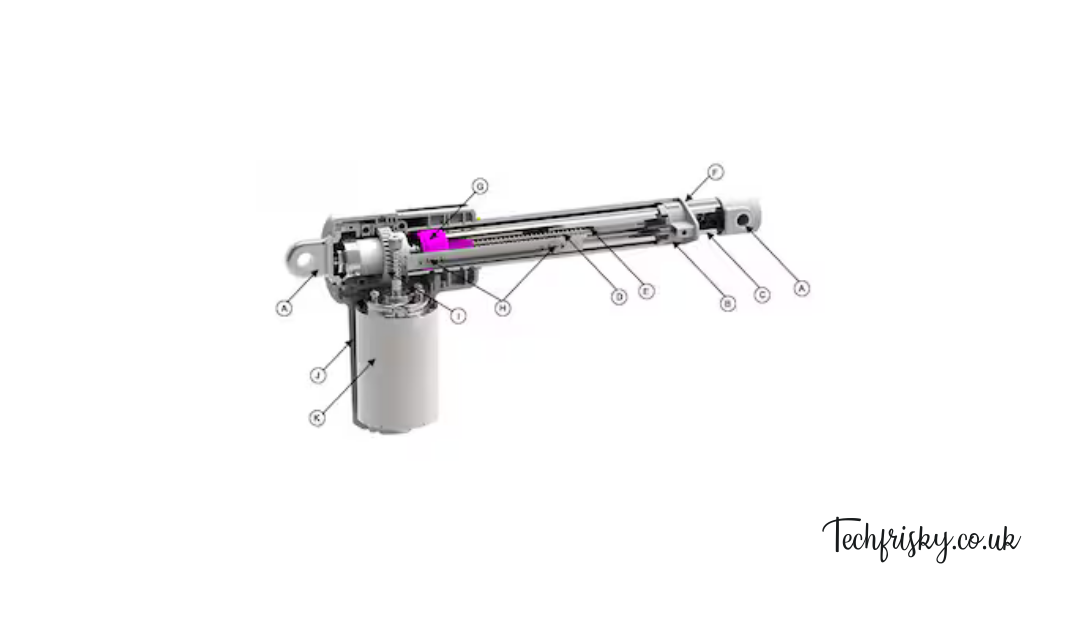

Core Components of an Electric Actuator

Understanding the core components of throttle actuator assembly for an electric boat rv4daysd602a provides insight into their operation:

- Motor: The powerhouse, generating motion.

- Housing: Protects components from environmental factors.

- Power Source: Powers the actuator, ranging from battery to direct electrical connection.

- Control Unit: Manages the actuator’s movement, crucial for precision applications.

Each component works harmoniously to deliver accurate and reliable performance in diverse environments.

How Do Electric Actuators Work?

throttle actuator assembly for an electric boat rv4daysd602a convert electrical energy into mechanical energy using a motor-driven mechanism. Upon receiving electrical signals, the actuator’s motor generates movement, either in a linear or rotary direction. This energy transformation is controlled by a microprocessor, allowing for precise positioning and movement, essential in tasks requiring high accuracy, such as robotic arms or conveyor systems.

Types of Electric Actuators: Linear and Rotary

- Linear Actuators: Generate movement in a straight line, commonly used in adjustable beds, industrial machinery, and automated doors.

- Rotary Actuators: Produce circular motion, ideal for opening valves or rotating levers.

The choice between linear and rotary depends on the specific application and the type of motion required.

Industries Where Electric Actuators Are Used

throttle actuator assembly for an electric boatare invaluable in fields such as:

- Automotive: Power windows, seat adjustments, and engine control systems.

- Aerospace: Flight control surfaces, landing gear.

- Robotics: Precision control in robotic arms.

- Industrial Manufacturing: Packaging, assembly lines, and quality control processes.

Their adaptability and performance make them essential in any industry relying on automated systems.

How Electric Actuators Provide Superior Precision and Control

throttle actuator assembly for an electric boat rv4daysd602a are engineered for superior precision and repeatability, essential in applications that demand fine control. Integrated control systems allow users to adjust speed, position, and force in real time, enabling automation in manufacturing, healthcare, and laboratory applications.

Customization Options in Electric Actuators

Electric actuators can be tailored to meet unique industry requirements, with options for varying:

- Torque: Adjustable based on load requirements.

- Speed and Range: Customizable for applications with specific movement needs.

- Control Options: Integration with smart technology or manual controls.

Customization enhances the adaptability of throttle actuator assembly for an electric boat in specialized roles.

How Durable Are Electric Actuators and Maintenance Requirements

Electric actuators are generally durable, with life spans that exceed hydraulic and pneumatic counterparts when maintained properly. Maintenance requirements typically involve regular inspection and lubrication to prevent wear.

Environmental Considerations and Sustainability of Electric Actuators

throttle actuator assembly for an electric boat offer sustainable solutions with minimal environmental impact. Without the need for hydraulic fluids, they eliminate leakage and reduce environmental risks. In addition, they consume energy more efficiently, which helps to lower emissions when compared to other actuator types.

Safety Mechanisms in Electric Actuators

Safety mechanisms include emergency shut-off switches, overload protection, and built-in diagnostics that prevent failure. These features ensure both user safety and device longevity.

Latest Innovations in Electric Actuators

Recent innovations have focused on integrating throttle actuator assembly for an electric boat with IoT systems, enabling remote monitoring, predictive maintenance, and advanced control features. These improvements are setting new standards for efficiency and functionality.

Factors to Consider When Choosing an Electric Actuator

Selecting the right throttle actuator assembly for an electric boat rv4daysd602a depends on factors such as:

- Torque and Speed Requirements: Dependent on application demands.

- Compatibility with Control Systems: Integration capabilities.

- Cost and Maintenance Needs: Weighing upfront costs against maintenance and longevity.

Future Trends in Electric Actuator Technology

Future trends indicate increased integration with AI and machine learning, enabling throttle actuator assembly for an electric boat rv4daysd602a to predict and adjust movements, optimizing efficiency and precision. Additionally, the move towards sustainable solutions is driving the development of green actuators with even lower energy consumption.

Frequently Asked Questions

1. What types of electric actuators are available?

- Linear and rotary electric actuators, used for different motion needs.

2. How often should electric actuators be maintained?

- Routine inspections every 6-12 months, depending on usage.

3. Can electric actuators be customized?

- Yes, customization is available for speed, torque, and control features.

4. What industries use electric actuators?

- Automotive, aerospace, robotics, and industrial manufacturing.

5. Are electric actuators environmentally friendly?

- Yes, they are generally eco-friendly due to low energy consumption.

6. How do electric actuators differ from hydraulic ones?

- Throttle actuator assembly for an electric boat rv4daysd602a are more efficient, require less maintenance, and are easier to integrate with electronic control systems.

Conclusion

Electric actuators are integral to modern automation, enhancing precision and control across numerous industries. Their versatility, combined with environmental benefits, positions them as a future-forward choice in a world increasingly driven by automated systems.